Introduction

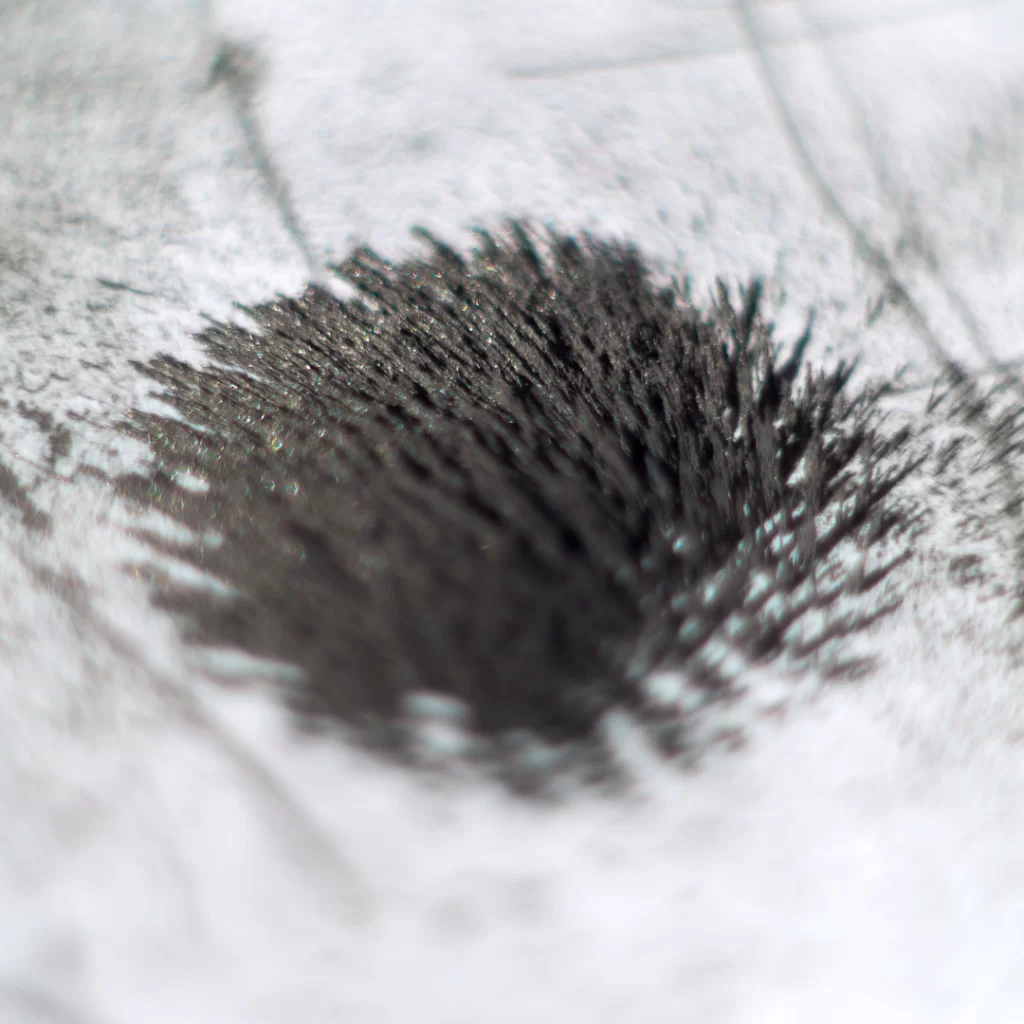

Microstructures, the tiny patterns and arrangements of materials at the microscopic level, hold valuable insights into the properties and behavior of various materials. Optical microscopes provide a window into this hidden world, allowing us to observe and analyze microstructures with great detail. Grain size analysis is a crucial task in materials science and engineering for quantifying the microstructure. Traditionally, grain size analysis involved time-consuming, error prone, manual measurements from the images obtained from optical microscopes. However, with the advent of computer vision techniques, we can now automate and streamline this process, enabling faster and more accurate grain size analysis. In this blog, we will explore the application of computer vision in grain size analysis of microstructures obtained from optical microscopes, showcasing its benefits and highlighting real-world examples.

Significance of Grain size analysis

It provides valuable insights into the mechanical, thermal, electrical, and functional properties of materials, making it a crucial parameter for material characterization and process optimization.

- Material Properties

Grain size directly influences the mechanical properties of materials, such as strength, hardness, ductility, and toughness. Smaller grain sizes often result in improved mechanical properties due to increased grain boundary strengthening. Understanding the grain size distribution helps engineers and scientists predict and control material behavior under different conditions.

- Material Selection

Grain size analysis assists in material selection for specific applications. Different grain sizes exhibit varying properties, making it essential to identify the optimal grain size for a particular use. For instance, fine-grained materials are often preferred for applications requiring high strength and fatigue resistance, while coarse-grained materials may be suitable for improved formability or increased thermal stability.

- Quality Control

Grain size analysis serves as a quality control tool in manufacturing processes. It helps ensure that materials meet required specifications and standards. Deviations in grain size can indicate processing inconsistencies or potential defects, enabling early detection and prevention of material failures. Industries such as aerospace, automotive, and electronics rely on accurate grain size analysis to maintain high-quality products and ensure reliability.

- Process Monitoring and Optimization

Continuous monitoring of grain size during manufacturing processes is crucial for process control and optimization. Real-time analysis can identify process variations, allowing for immediate corrective actions and ensuring consistent product quality. By monitoring grain size distribution, engineers can optimize processing parameters, reduce material waste, and improve overall process efficiency.

Different techniques for measuring Grain size

American Society for Testing and Materials (ASTM) E112 Standard Test Method is one of the standard followed for determining average grain size. This standard also talks about the sample preparation for grain size analysis ( in this blog we will not be covering those details). Following are the methods the standard specifies:

- Visual comparison with the standard grain size charts

This method is commonly used in grain size analysis to provide a qualitative assessment of grain sizes. In this method the microstructure is visually compared with a standard grain size charts and determine the grain size. These charts typically consist of a range of images or diagrams showing microstructures with varying grain sizes, from fine to coarse. By visually comparing the microstructure of the sample under analysis with the grain size charts, one can estimate the approximate grain size based on similarity or by identifying the most representative image. Visual comparison methods are subjective and rely on the experience and expertise of the analyst.

- Planimetric analysis

Planimetric analysis is a quantitative method used in grain size analysis to measure the size and distribution of grains within a microstructure. It involves determining the projected area of individual grains from two-dimensional micrographs and using this data to calculate various grain size parameters. The grain size parameters are then calculated based on the measured projected areas. The most commonly used parameters include average grain size, median grain size, grain size distribution, and various statistical parameters such as standard deviation or percentiles. These parameters provide quantitative information about the grain size distribution within the microstructure

- Intercept analysis

The intercept method is a widely used quantitative technique for grain size analysis. It involves measuring the lengths of grain boundaries intersected by a set of straight lines, known as intercepts, within a microstructure. These measurements are then used to estimate the average grain size. It is estimated by dividing the total length of intercepts by the total number of grain boundaries intersected. Other parameters such as median grain size, grain size distribution, and statistical measures can also be derived from the intercept data.

Implementing the calculations with computer vision techniques

Following are the steps for measuring the grain size using CV techniques:

- Image Preprocessing

Image preprocessing is a crucial step that prepares microstructure images for further analysis. Techniques such as image denoising, contrast enhancement, and image normalization can help remove noise, enhance details, and standardize image properties. Filtering methods like Gaussian smoothing, median filtering, or adaptive histogram equalization can be applied to improve the quality and enhance the features of microstructure images.

- Grain Boundary Detection and Segmentation

Segmentation is the process of dividing an image into meaningful regions based on certain characteristics. In microstructure analysis, segmentation is used to separate individual grains, or features within the microstructure. Various segmentation techniques can be employed, such as thresholding, region growing, edge detection, or clustering algorithms. These techniques allow for the identification and isolation of individual grains, enabling further analysis and characterization.

- Grain Size Measurement

Implement the appropriate measurement method specified in ASTM E112 to determine the grain size.

Conclusion

Computer vision has revolutionized grain size analysis by enabling automated and efficient analysis of microstructures obtained from optical microscopes. Through advanced algorithms and techniques, we can accurately segment grains, detect grain boundaries, and quantify grain size. This automated approach significantly reduces analysis time, eliminates human subjectivity, and opens up new possibilities for materials research and development. As computer vision continues to advance, we can expect further enhancements in accuracy, speed, and the application of deep learning methods. By leveraging the power of computer vision, we can unlock a deeper understanding of material microstructures and drive innovation in various industries